An Advantage of the Axial Flow Compressor Is Its

B As this compressor does not require any special foundation it is highly energy efficient and reliable. Low manufacturing and running costs.

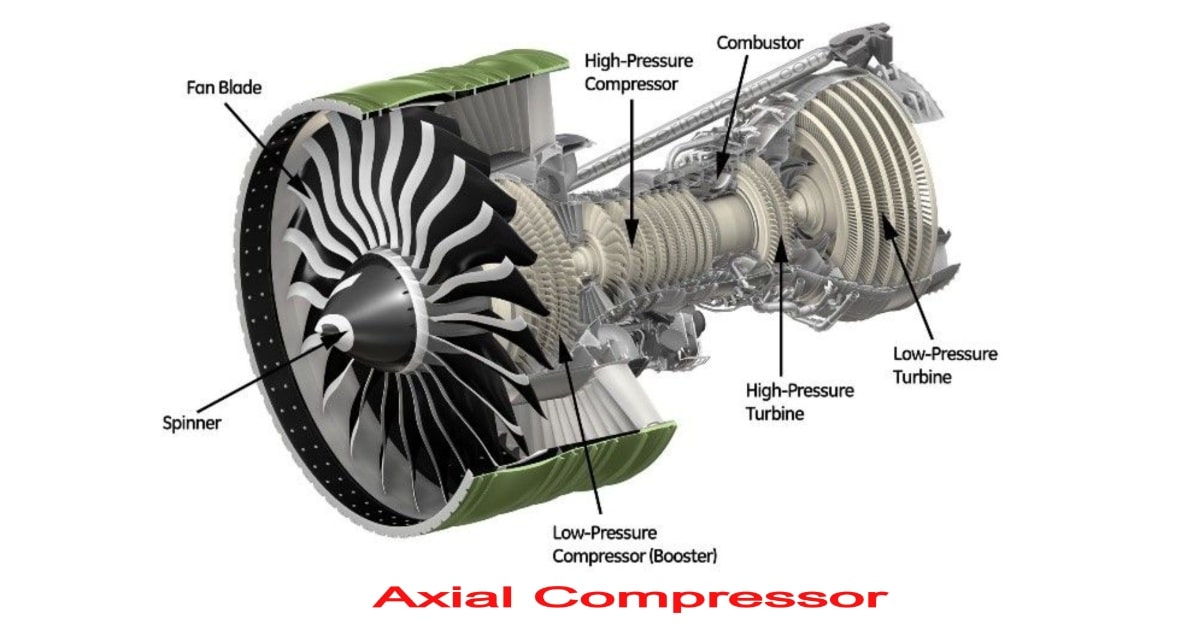

Axial Flow Compressor Parts Working Diagram Advantages Application

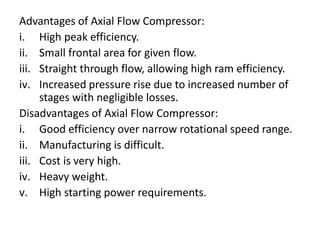

-Straight-through flow allowing high ram efficiency.

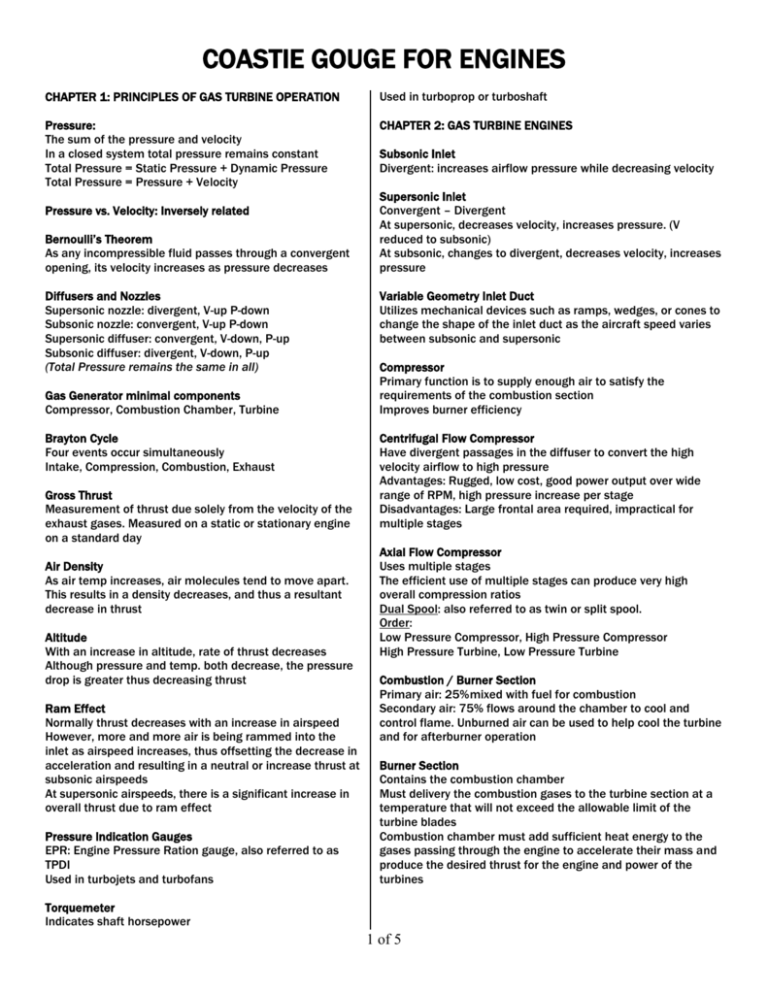

. The axial-flow compressor compresses its working fluid by first accelerating the fluid and then diffusing it to obtain a pressure increase. Centrifugal compressors are reliable low maintenance. It probably is one of the most crucial and complex turbo-machines at many process plants.

Aerofoil blades are used. Achieving and maintaining desired performance depends upon properly addressing some complicated design. The industrial gas turbine has always emphasized long life and this conservative approach has resulted in the industrial gas turbine in many aspects giving up high performance for rugged operation.

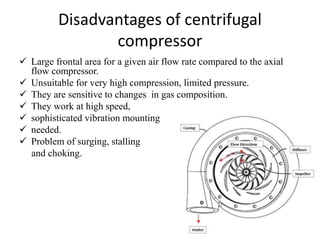

Centrifugal compressor Axial Flow Compressor. D It generates a higher pressure ratio per. -Small frontal area forgiven airflow.

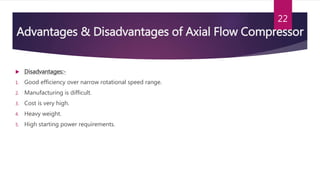

Not suitable for multi-staging. An axial compressor is a compact turbo-compressor that suits applications with a very large flow and a relatively small pressure difference head. 79 8186 - The purpose of a bleed valve located in the beginning stages of the compressor in an aircraft gas turbine engine is to.

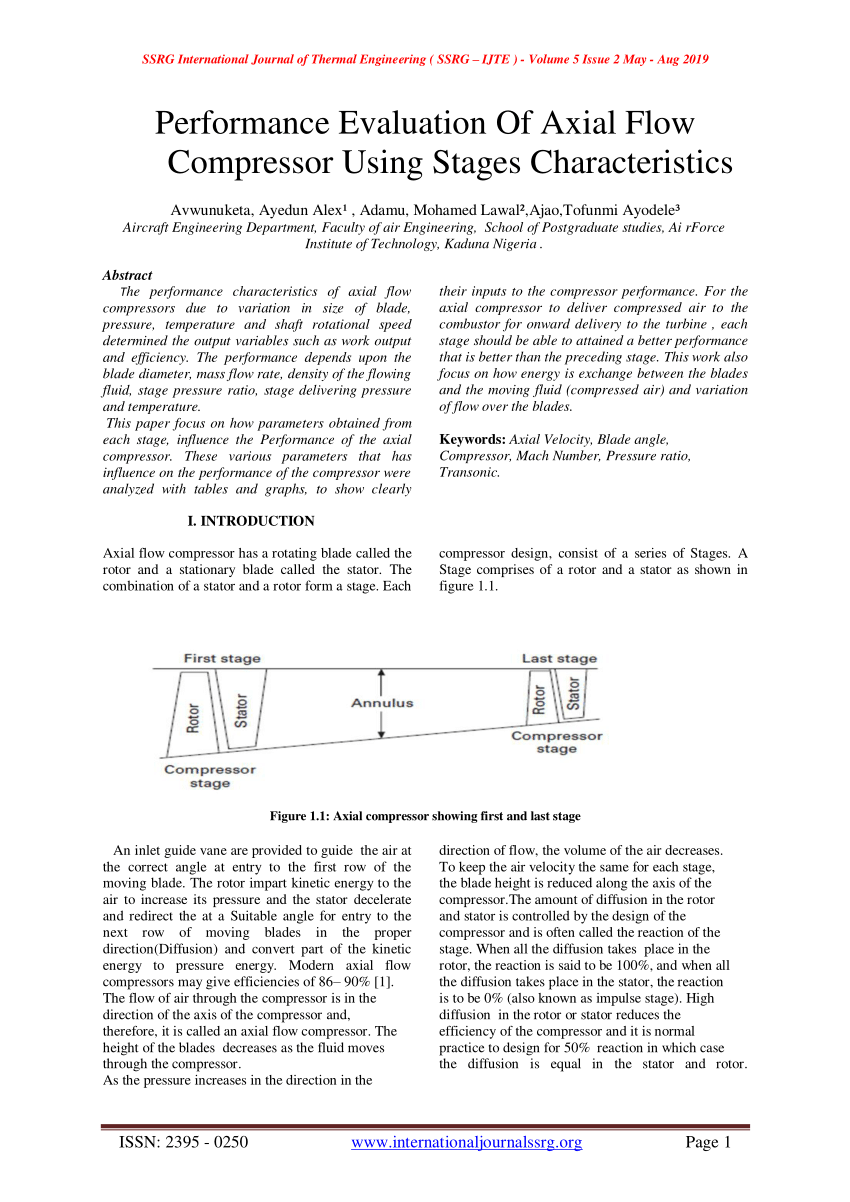

Similarly one may ask what is an advantage of the axial flow compressor. 78 8185 - What is the primary advantage of an axial-flow compressor over a centrifugal compressor. Through a stage in axial flow compressor A stage is a pair of rotating airfoil and stationary airfoil in an axial flow compressor.

Generating a higher pressure ratio per stage as compared to axial flow compressor. Axial flow compressors produce a continuous flow of compressed gas and have the benefits of high efficiency and large mass flow rate particularly in relation to their size and cross-section. May 06 2014.

Pressure rise per stage. By Chad Trautvetter - December 5 2016 100 PM. The compression cylinder also support the filters and the oil lubrication systems.

Stages Of Axial Flow Compressor 1267 Words 6 Pages. Larger air handling ability per unit frontal area. This makes it better suited to applications where the thrust of the engine itself is the motive force for the aircraft.

2 It is more suitable for multi staging increase in pressure with negligible losses. An advantage of the centrifugal-flow compressor is its high A. What is the primary advantage of an axial flow compressor over a centrifugal flow compressor in a turbine aircraft engine.

As the air passes through the rotating airfoil also called a blade or rotor its velocity increases. Advantages of the axial compressor are its higher flow rate and greater pressure ratio which results in higher thrust and fuel efficiency. Axial compressors have the best efficiency.

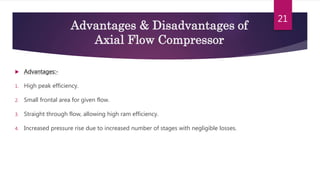

What is the function of the inlet guide vane assembly on an axial flow compressor. Advantages of Axial flow Compressor. Advantages of axial flow compressor are as follows 1 It has higher efficiency than a centrifugal compressor.

Compressors are typically driven by an electric motor or a steam or a gas turbine. C They consist of a small number of rubbing parts and are absolutely oil free in nature. Both mechanical and aerodynamic losses for an axial compressor are very low resulting in efficiencies approaching 90 or even better.

Due to the configuration of the axial the sealing surface is very small in. Flow is perpendicular to the axis of the compressor. Wide range of rotational speed.

High-flow rate than the positive displacement compressor. Requires low starting torque. 3 The pressure ratio of 81 or even higher can be achieved using a multi-stage axial flow compressor.

An advantage of the axial-flow compressor is its- 1. This makes it better suited to applications where the thrust of the engine itself is the motive force for the aircraft. C- Greater pressure ratio.

Advantages of the axial compressor are its higher flow rate and greater pressure ratio which results in higher thrust and fuel efficiency. Like an axial flow compressor a screw compressor can also be made multi-staged by incorporating multiple cylinders. High manufacturing and running costs.

Axial-flow compressors have the following advantages. Axial flow compressor has the following advantage over centrifugal compressor. The compressor draws air from the atmosphere and it may contain several impurities.

Converts velocity energy into pressure energy. Each cylinder will have its own rotor assembly. The flow of air is parallel to the axis of compressor.

Higher pressure ratio per stage. Requires high starting torque.

Comparison Centrifugal And Axial Compessor

What Is The Difference Between Axial And Centrifugal Compressors Quora

Comparison Centrifugal And Axial Compessor

Axial Flow Compressors An Overview Sciencedirect Topics

Pdf Performance Evaluation Of Axial Flow Compressor Using Stages Characteristics

Why Do Airplanes Use An Axial Flow Jet Engine Instead Of A More Compact Centrifugal Jet Engine Aviation Stack Exchange

Advantages Disadvantages And Applications Of Centrifugal Compressor Mecholic

Jet Propulsion The Jet Engine I Lecture One

Axial Flow Compressor Components Working Advantages Disadvantages Applications Losses And Velocity Diagram

Ppt Axial Flow Compressor Powerpoint Presentation Free Download Id 2518999

Turbine Engine 101 Topics History Of Turbine Engine Design Types Of Turbine Engines Common Turbine Engine Models Found On Today S Private And Corporate Ppt Download

Axial Compressor Definition Working Components Construction Applications Advantages Disadvantages Engineering Learn

What Is The Difference Between Axial And Centrifugal Compressors Quora

What Are The Disadvantages And Advantages Of Axial And Centrifugal Compressors Quora

Comments

Post a Comment